Switching to imaging-based particle measurement represents a fundamental transformation in how industries assess and quantify particulate matter, and understanding the economic implications of this transition is essential for informed decision making. While traditional methods such as optical particle counting or weight-based methods have dominated for decades, imaging systems now offer high-fidelity insight by capturing high-resolution images of each particle, enabling not just size and count measurements but also particle geometry, surface texture, and chemical signature.

The upfront costs of adopting imaging technology can be significant, including the purchase of high-resolution cameras, advanced lighting systems, powerful computing hardware, and specialized software for deep learning-based classification and defect detection. Additionally, training personnel to operate and interpret results from these systems requires investment in education and time.

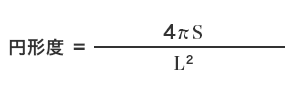

However, 粒子径測定 these initial expenses are often eclipsed by enduring productivity gains. Imaging-based systems cut down on hands-on handling and prevent costly re-runs caused by ambiguous outputs, which in turn cuts staffing overhead and maximizes throughput.

In industries such as biotech, microelectronics, and beverage manufacturing, where quality standards are extremely stringent, the improved accuracy of imaging leads to decreased withdrawal incidents, smoother audits, and increased customer loyalty.

Regulatory bodies increasingly insist on auditable, objective metrics, and imaging systems provide auditable visual evidence that simplifies audits and inspections. Furthermore, because these systems can detect anomalies that other methods miss, they enable earlier identification of contamination sources, preventing major operational delays.

Over time, the reduction in waste, improved yield, and greater confidence in quality control contribute to a strong financial payoff.

Companies that transition early also gain a competitive advantage by optimizing their processes faster and positioning themselves as leaders in innovation and quality.

Although the path to implementation requires detailed roadmap development and resource allocation, the economic benefits—spanning operational efficiency, compliance security, and output growth—make imaging-based particle measurement not just a system modernization but a wisely calculated investment.