In the pharmaceutical industry, ensuring the quality of raw materials is a critical step that directly impacts the safety, efficacy, and consistency of final drug products. Conventional quality checks typically involve lengthy lab procedures like HPLC, FTIR, or laser diffraction—all of which require sample preparation, calibration, and extended analysis periods. Extended analysis times may lead to production holdups and potential compliance violations.

Dynamic imaging offers a transformative approach to this challenge by enabling instant, real-time, and comprehensive analysis of pharmaceutical raw materials in real time.

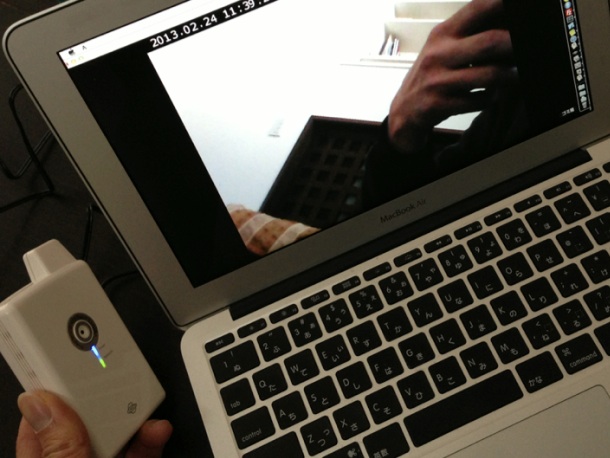

Dynamic imaging systems utilize high speed cameras and advanced lighting configurations to capture a sequence of images as materials move through a process stream or are dispensed onto a conveyor. Unlike static imaging, which records a single snapshot dynamic imaging captures motion and physical behavior—including particle flow dynamics, clumping behavior, surface roughness evolution, and segregation trends—over time. The motion-based data reveals patterns invisible to static analysis, allowing operators to detect anomalies that appear only under motion or during handling.

One of the most significant advantages of dynamic imaging is its ability to assess several critical parameters in parallel. For instance, it can measure granule size gradients, spot powder clustering, track airborne particulates, and flag contaminants or color anomalies—all within seconds. These insights are vital when handling high-potency actives, diluents, and multi-component blends, where slight variations may cause tablet friability issues, delayed release kinetics, or dose variability.

The technology is often integrated into continuous monitoring stations positioned adjacent to processing units, making it compatible with existing manufacturing environments. When paired with deep learning classifiers, dynamic imaging systems can establish baseline behavior profiles and detect statistical outliers. This foresight allows proactive adjustments, cutting down on waste and unplanned stoppages.

Moreover, dynamic imaging supports regulatory compliance by generating verifiable, digitally archived, and time-stamped video evidence. Regulatory agencies such as the FDA and EMA increasingly encourage the adoption of process analytical technologies for real time quality assurance. Dynamic imaging aligns with these guidelines by providing a continuous, data rich monitoring solution.

Implementation does require careful consideration of lighting calibration, resolution settings, and material conveyance parameters to ensure image quality and accuracy. However, modern systems are designed with pharmaceutical environments in mind, featuring stainless steel construction, easy cleaning protocols, and compliance with cGMP standards. Operators require only basic instruction, thanks to user-friendly UIs and AI-driven alerting.

As the pharmaceutical industry continues to embrace data-driven innovation and end-to-end process optimization, dynamic imaging stands out as a essential solution for real-time input validation. It links traditional assays with live operational feedback, offering real-time insight with lab-grade accuracy that static analyses lack. By adopting dynamic imaging, manufacturers can not only enhance throughput while maintaining compliance but also build more resilient, 粒子形状測定 responsive, and data driven production systems that safeguard patient health and meet evolving regulatory expectations.