Ensuring reliable ink consistency remains a core concern in diverse fields including industrial printing, packaging, electronic circuits, and beauty product formulation

One often overlooked factor that significantly influences ink performance is the shape of the pigment and additive particles within the formulation

While particle size has long been the primary focus of quality control, the geometry of those particles—whether they are spherical, rodlike, platelet-shaped, or irregular—plays an equally vital role in determining flow behavior, color intensity, stability, and final print quality

Adopting sophisticated morphological analysis techniques enables manufacturers to attain levels of formulation precision and product reliability previously unattainable

Ink formulation has long depended on empirical adjustments of composition variables, often without correlating changes to underlying particle geometry

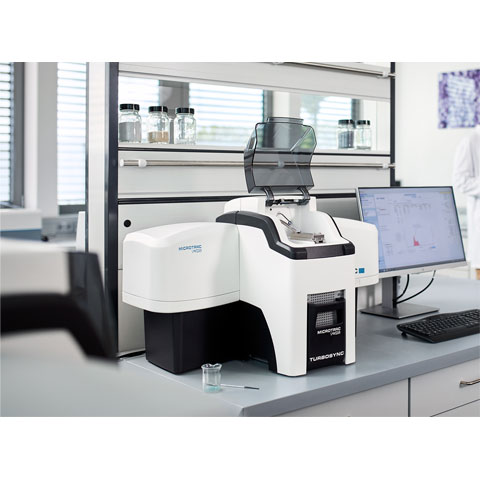

However, modern imaging and computational techniques now allow for precise characterization of particle shapes in three dimensions

Dynamic imaging, multi-angle laser scattering with morphology filters, and automated SEM analysis deliver comprehensive metrics on particle geometry including sphericity, surface texture, 動的画像解析 and axial ratios

The derived data uncovers tendencies for particles to clump, sink, or align in response to shear stress during formulation and application processes

Spherical morphologies promote even flow dynamics and resist settling, rendering them optimal for fast-moving printing lines

Flake-like particles boost hiding power and shine through layered alignment upon drying, yet they may induce angle-dependent color variations due to preferential orientation

Elongated particles contribute to film toughness, but uncontrolled aspect ratios between production runs can destabilize viscosity and compromise print consistency

Grasping these morphology-performance links empowers developers to source or design particles tailored to distinct application demands

The uniformity of particle geometry is a fundamental driver of colloidal stability

Irregularly shaped particles have higher surface energy and more points of contact, which can lead to increased agglomeration

This results in inconsistent color density, poor print resolution, and potential clogging of nozzles in inkjet systems

By analyzing shape distributions over time and across production batches, manufacturers can identify deviations early and adjust milling processes, surfactant types, or mixing parameters to maintain optimal morphology

Moreover, regulatory and environmental pressures are driving the industry toward more sustainable formulations

By tailoring particle geometry, manufacturers can achieve higher performance with lower pigment loading, minimizing raw material consumption

Optimally shaped pigments can match color intensity at reduced concentrations, cutting both material expenses and ecological footprints

This approach supports the creation of aqueous and solventless formulations, whose performance is heavily influenced by particle shape owing to altered interfacial behavior and evaporation profiles

Initial investment in instrumentation and staff training is offset by major operational benefits

Consistent shape profiles decrease reject rates, shorten changeover times, and elevate overall customer experience

It also accelerates new product development by providing clear, data-driven guidelines for formulation changes rather than relying on subjective assessments

This approach signifies a fundamental evolution from troubleshooting to predictive, morphology-guided formulation science

By treating particle geometry as a critical parameter alongside size and composition, manufacturers can unlock greater control over ink performance, durability, and reliability

As technology continues to evolve, integrating shape analysis into standard quality protocols will become not just advantageous but essential for staying competitive in a demanding global market